We produce comprehensive material selection reports that guide companies in new project designs, informing them of all potential risks to materials and recommending effective mitigations.

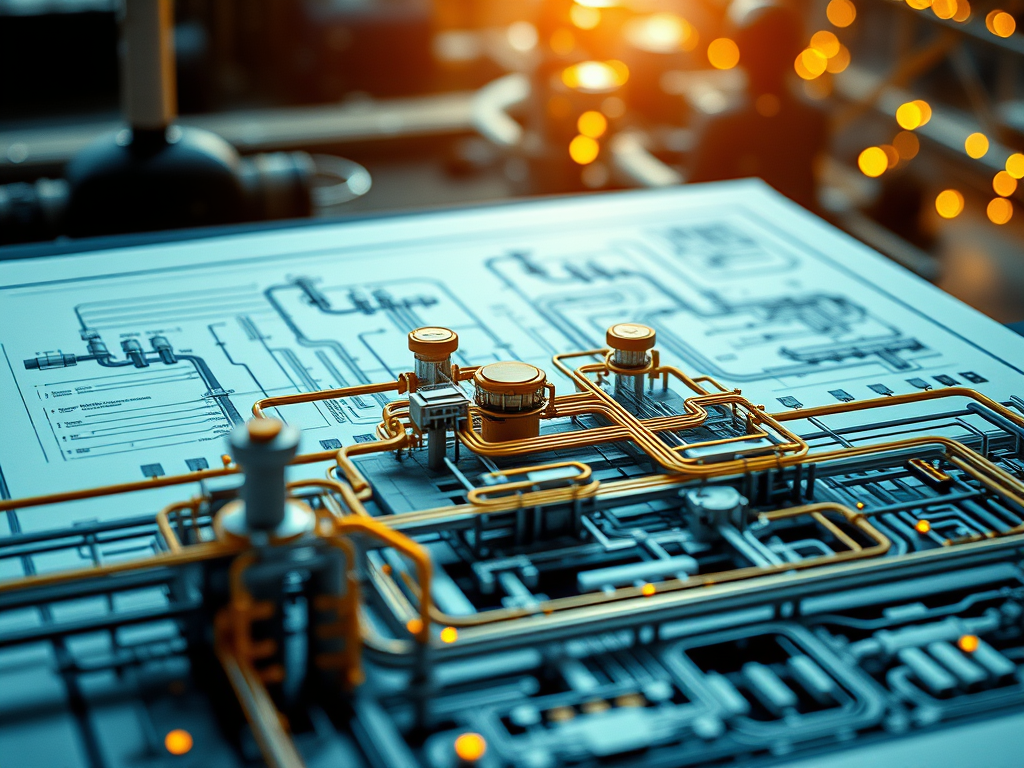

Front-End Engineering Design (FEED)

Corrosion Risk Assessment

We evaluate potential corrosion threats during the initial design phase. Additionally, we analyze process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs) to identify vulnerable areas.

Material Selection Reports

We provide comprehensive reports on the suitability of materials based on design specifications and anticipated service conditions. Our reports include recommendations for materials that offer the best resistance to corrosion.

Review Design and Field Operating Conditions

We conduct a thorough review of design data and actual field operating conditions, parameters, analysis, issue comprehensive reports identifying potential corrosion risks and appropriate mitigation to ensure the integrity of the assets.

Piping and Instrumentation Diagram (P&ID) Review

Detailed Review

Conduct a thorough review of P&IDs to identify potential corrosion risks and we ensure the diagrams accurately represent the system design and operational parameters.

Material Selection

We evaluate and select appropriate materials during the review process to ensure optimal corrosion resistance.

Recommendation

We provide recommendations for modifications or enhancements to minimize corrosion

risks identified during the review and we ensure the risk is as low as reasonably practicable (ALARP) to the assets.

Hazard and Operability Studies (HAZOP)

Corrosion Hazard Identification

We identify and assess corrosion hazards during the HAZOP studies. We focus on process deviations that could lead to increased corrosion risks

Material Selection

We assess and recommend materials that mitigate identified hazards to ensure long-term integrity of the assets

Mitigation Strategies

We develop and recommend mitigation strategies to address identified corrosion hazards, ensuring safer, more reliable operations and risks are as low as reasonably practicable (ALARP)

3D Modeling and Simulation Phase

Design

We provide aid and guidance to companies during the 3D modeling phase by identifying corrosion-prone areas in the facility design. This helps in preemptively addressing potential issues that may arise during actual Construction.

Material Selection

We ensure material selection is incorporated into the 3D modeling process, allowing for a comprehensive assessment of potential corrosion scenarios, thereby ensuring the integrity of assets is maintained during construction.

Recommendations

We provide recommendations that take into account potential site constraints and budgetary limitations. This approach enables our clients to make informed decisions on design and material selection, thereby ensuring both economic efficiency and the integrity of assets

Detailed Engineering Phase

Corrosion Assessments

We perform detailed corrosion assessments for clients during the detailed engineering phase to identify any emerging risks and ensure proper implementation of corrosion mitigation strategies. This is based on both design and actual field analysis data.

Material Selection

We provide our clients with recommendations for selected materials, ensuring they meet the required specifications for corrosion resistance. Additionally, we offer suitable mitigation strategies for all identified corrosion risks to these materials, safeguarding their integrity and longevity

Document Review

We review all design documentation for our clients related to corrosion risks, assessment and material selection

Construction Phase

Corrosion Assessment

We perform on-site corrosion assessments during the construction phase to identify any emerging risks and ensure proper implementation of corrosion mitigation strategies

Material Selection Verification

We verify the selected materials are used correctly and they meet the required specifications for corrosion resistance

Quality Control and Quality Assurance

We implement rigorous quality control and quality assurance processes to monitor and document adherence to design specifications, material selection, and corrosion mitigation strategies during the construction phase. This ensures that all project aspects meet our high standards, safeguarding the safety and integrity of assets.